-

Air Operated Diaphragm Pump

-

Pneumatic Diaphragm Pump

-

Sanitary Pneumatic Diaphragm Pump

-

Stainless Steel Diaphragm Pump

-

Polypropylene Diaphragm Pump

-

Plastic Diaphragm Pump

-

Aluminum Diaphragm Pump

-

Motor Diaphragm Pump

-

AODD Pump

-

Chemical Diaphragm Pump

-

Electric Diaphragm Pump

-

Diaphragm Pump Parts

-

Waste Water Diaphragm Pump

| Highlight | 3 Inch Stainless Steel Diaphragm Pump,Stainless Steel Double Diaphragm Pump,Stainless Steel Diaphragm Pump Water Transfer |

||

|---|---|---|---|

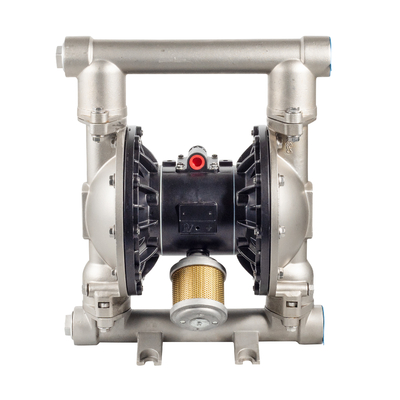

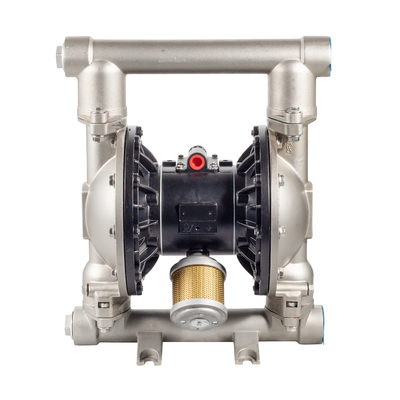

11/2 Inch Stainless Steel Air Operated Pneumatic Water Oil Lotion Acid Transfer Double Diaphragm Pump

INTRODUCTION

Stainless Steel diaphragm pump is used where there is a demand for high pumping performance, combinations of both hot and corrosive fluids, both acidic and alkali. They are the ultimate choice for durable long life performance.

RV offers some class leading diaphragm materials in combination with these pumps to tackle some of the most difficult pumping applications.

| Max Working Pressure | 120 psi(0.84Mpa, 8.4bar) |

| Max Flow Rate | 90gpm(340lpm) |

| Max Reciprocating Speed | 200cpm |

| Max Suction Height (Dry Sucking) | 5m |

| Max Permitted Grain | 0.2 inch (5mm) |

| Max Air Consumption | 80scfm(90L/s) |

| Air Inlet Size | 1/2inch |

| Air Outlet Size | 3/4 inch |

| Fluid Inlet Size | 1-1/2inch |

| Fluid Outlet Size | 1-1/2 inch |

| Net Weight | Stainless Steel 30.7 kgs |

| Type of Diaphragm | IMAGE | Typical Usage |

| PTFE | Excellent choice when pumping highly aggressive fluids such as aromatic or chlorinated hydrocarbons, acids, caustics, ketones and acetates. Temperature range +4°C to +104 C (+40 F to +220F) |

Packing & Shipping:

![]()

![]()

DIAPHRAGM OPTIONS

PTFE

Santoprene

Buna-N

Hytrel

Viton

Neoprene

VERSATILITY

This air diaphragm pump handles viscous fluids, slurries, solid laden fluids, no priming needed, no foaming of fluid pumped, no stall damages, portable

![]()

![]()

INSTALLATION

Be sure the mounting can support the weight of the air diaphragm pump, hoses, and accessories, as well as the stress during operation progress.

During installation, make sure that the air diaphragm pump has been fixed with bolts on the mounting feet.

In order to facilitate the operation and maintenance, the maintenance space should be enough during installing the air diaphragm pump.

While fastening the air diaphragm pump, rubber pad can be padded to reduce the noise and vibration during operation.